The difference between electrical and optical strain gauge sensors

10

Feb 21The difference between electrical and optical strain gauge sensors

- 10 February 2021

- Redazione_AEP

- estensimetri elettrici sensore ad estensimetro sensori estensimetrici ottici strain-gauge sensors

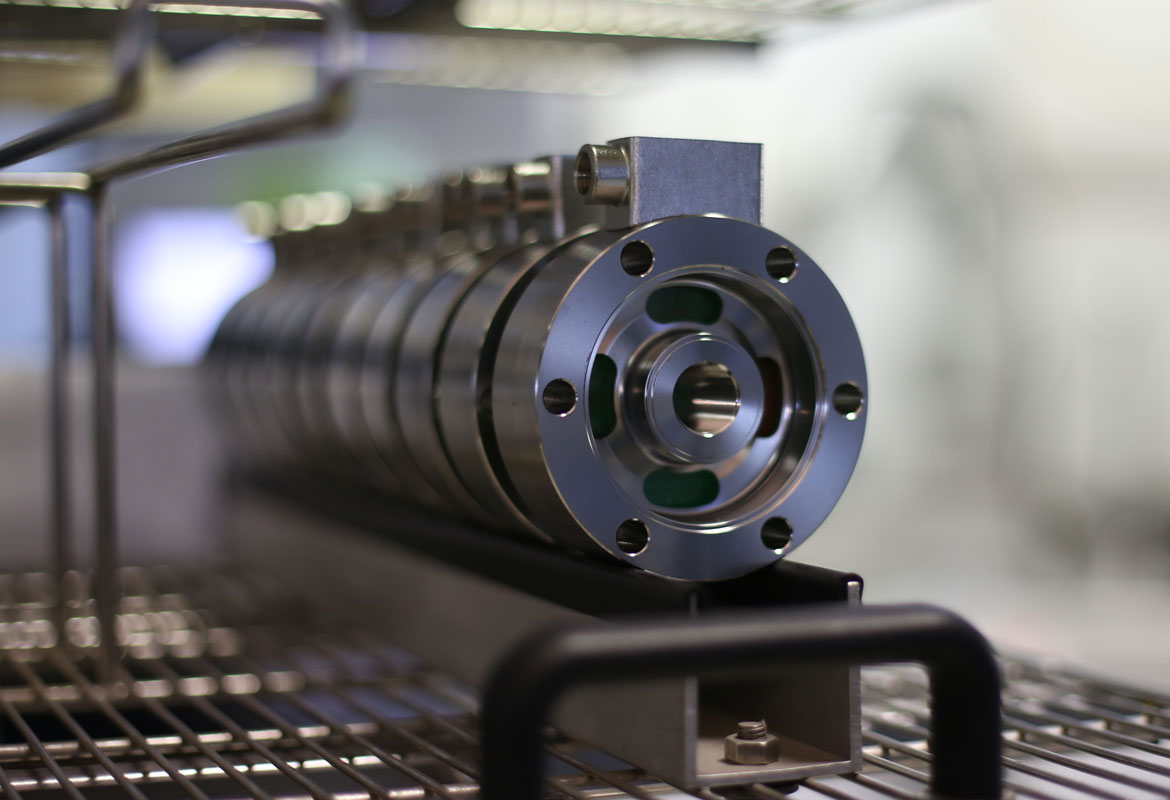

Our company has been producing accurate, functional and quality strain gauge sensors for many years. Therefore, over the years we have analysed numerous solutions and followed the progress of technology step by step. With this in mind, we would like to share some of our knowledge with you today by telling you about the difference between electrical and optical strain gauge sensors.

Let’s start with the basics: what is a strain gauge sensor?

In order to optimally evaluate and measure mechanical forces, numerous calculations need to be made. Fortunately, nowadays we can rely on various technologies and, more specifically, on the functionality of different strain gauge sensors. Strain gauges allow force to be measured by means of an element made of a strong elastic material inside the sensor.

The force is applied to this element. Of course, this causes a slight deformation of the spring element, through which the applied force can be measured. Depending on the size of the spring element, the measuring range of the device in question can be determined.

Electrical strain gauges

Electrical strain gauges are based on one of the most proven technologies in the industry. They ensure the acquisition of correct values by measuring the change in electrical resistance in a given component. For these reasons, they are excellent for experimental stress analysis or for manufacturing transducers.

In addition, electrical strain gauge sensors are very popular because they can measure mechanical strain by means of films integrated in a load cell or force transducer. In order to acquire a positive or negative strain, a change in the electrical resistance of the strain gauge in question is required.

This type of product is available in a number of different models, which offer various measurements, such as linear strain measurement in a single axial plane.

Optical strain gauge sensors

Optical strain gauges use the properties of light and an optical fibre to measure mechanical strain. They consist of silicon optical fibres, coated with robust polymers, and Bragg fibre. This combination improves the performance of strain gauge sensors.

The Bragg fibre is placed in the core of the optical fibre: these two components allow light to pass through the grooves and be reflected back through the bandgaps. Variations of the periods of the Bragg fibre are normally given by mechanical deformations, which cause variations of the light.

Finally, there is an interrogator connected to the optical fibre, which can scatter laser light of various wavelengths and analyse the reflected light via the optical sensor. The optical sensor measures the various mechanical deformations.

Which strain gauge sensors are suitable for your company?

If you have doubts about which product to implement in your daily work, we suggest you evaluate the solutions of AEP transducers. We offer modern and efficient strain gauge sensors with the best metrological characteristics. We are available to answer your questions and to guarantee accurate, functional and customized products.