06

Apr 21Force transducers: Piezoelectric sensors or strain gauge sensors?

- 6 April 2021

- Redazione_AEP

- force transducers, Piezoelectric sensors, Strain gauge sensors

When it comes to force transducers, two principles of operation are most frequently used: those based on the use of piezoelectric sensors and those based on the capabilities of strain gauges. Which are the best? It is more appropriate to say that in certain situations and in specific contexts one type of sensor is more appropriate than the other. So let’s get to know them in more detail. This will help you to understand which is the best solution in your case.

The main features of piezoelectric sensors

Piezoelectric sensors, which are used for force transducers, generally consist of two discs with a foil electrode between them. When a certain force is applied to these devices, an electrical charge is immediately generated. This charge is measured by a charge amplifier. In other words, the charge generated is directly proportional to the force that is applied to the transducer, and the amplifier enables the force to be measured.

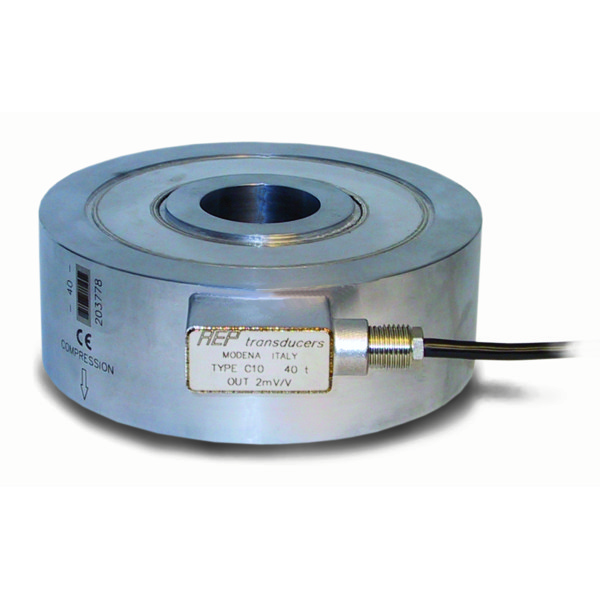

Force transducers with strain gauge sensors

A strain gauge sensor allows force to be measured in a different way. It always contains an element made of a strong, elastic material on which force is applied. This force clearly causes a slight deformation of the spring element, by which the applied force can be measured. Depending on the size of the spring element, the measuring range of the device can be determined.

Which sensor to choose?

In most cases, force transducers with piezoelectric sensors are the best choice if you are looking for an element that offers high stiffness. Consequently, they are even suitable for those who also want a high resonance frequency. Systems using a strain gauge sensor, on the other hand, have a relatively low resonance frequency.

In general, the choice of piezoelectric sensors is ideal for those who need to measure small forces quickly. Strain gauge operation is the best solution for those who need to measure large forces.

Support from professionals

Even those who have been using force transducers for a long time can benefit from the support of professionals. It is a good idea to get help from the companies that supply and, even better, manufacture these devices. Depending on the machinery, the working environment, the production methods, the specific needs and preferences, the experts can recommend the best sensor for the customer.

They can provide products suitable for even the harshest environments, such as IP68-rated force transducers and/or protective housings. Finally, professionals in the field can offer customised advice and a variety of solutions for those looking for high precision requirements as well as value for money.

Force transducers and sensors from AEP transducers

AEP transducers offers modern and efficient force transducers and sensors with the best metrological characteristics. Our laboratory is always working to ensure accurate, functional, robust and state-of-the-art products. We look forward to offering you customised solutions that are perfect for your working environment.

20

Mar 20For years we have been on the side of various types of industries and at the service of numerous sectors, dealing with the design, production and sale of many high quality components.

These include force transducers. Let’s see what this is all about and what we can guarantee you.

Do you know the force transducer?

For beginners, it is useful to point out that a force transducer is a device that converts a force into an electrical quantity.

In other words, we have an input force that is converted into an electrical signal proportional to the strain generated.

How a force transducer is made and how it works

Force transducers consist of a strain gauge, that is a resistive conductor applied to an insulating support and a spring element.

Usually, a strain gauge sensor consists of four strain gauges connected to a Wheatstone bridge and a spring element made from a mechanical structure.

The mechanical structure can be made with different geometries depending on the type of application, column, ring, membrane, etc…

When the mechanical structure extends, the strain gauges applied to the mechanical body are stretched.

When the mechanical structure contracts, the strain gauges are shortened, resulting in a change in resistance and consequently in the output voltage.

AEP transducers: design and manufacture of quality products

If your company needs the support of high quality force transducers, know that AEP transducers can certainly help you.

We are a team that specializes in the design and manufacture of these and many other products in the field of weight, force, pressure, torque and displacement measurement.

AEP markets force, pressure and displacement transducers, digital pressure gauges, load cells, torque transducers, dynamometers, electronic instrumentation and related application software.

All products manufactured are of the highest quality, reliability and stability over time.

They are certified according to ISO 376 and ASTM E74 standards and are extremely easy to use.

The products to be evaluated

- Star-F is a professional handheld indicator that measures displacement, torque, force, weight, pressure and depression.

It is equipped with a backlit graphic display and is powered by an internal rechargeable battery with 24 hours autonomy.

In addition to the internal sensor, it can alternatively manage up to 7 external sensors.

- CLF “Titan line” is a column force transducer able to measure static and dynamic loads in compression.

Entirely made of stainless steel, and LASER welded, it boasts an excellent mechanical resistance.

It is extremely stable and perfect for calibration of material testing machines.

- CFLEX is a transducer capable of calibrating the main force and checking the self-alignment of the joints.

It is also used in compression testing machines on hardened concrete for monitoring force centering.

It is made of laser welded stainless steel and equipped with 5 independent strain gauge bridges.

- CLB measures static and dynamic loads in traction and compression.

It is a column component, used for the tare weight of high class material testing machines,

This transducer is also laser welded and made of stainless steel.

- KAL and microKAL, on the other hand, are very precise force transducers for the tare weight of material testing machines and metrological comparisons between laboratories.

Our 50 years of experience allows us to guarantee all this and much more.

AEP transducers not only designs and manufactures force transducers and components of various kinds, but also provides consulting in the fields of metrology in various industrial sectors.