02

Apr 21Maintenance is an important operation in every case and in every sector. The maintenance of weighing systems is also important, especially in an industrial environment. If it is carried out correctly, it allows you to operate safely and maintain productivity and the quality of your products. With this in mind, let’s take a look at some tips that can help you save money and avoid any risks, simply by carrying out proper maintenance.

Preventive maintenance to reduce costs and increase system efficiency

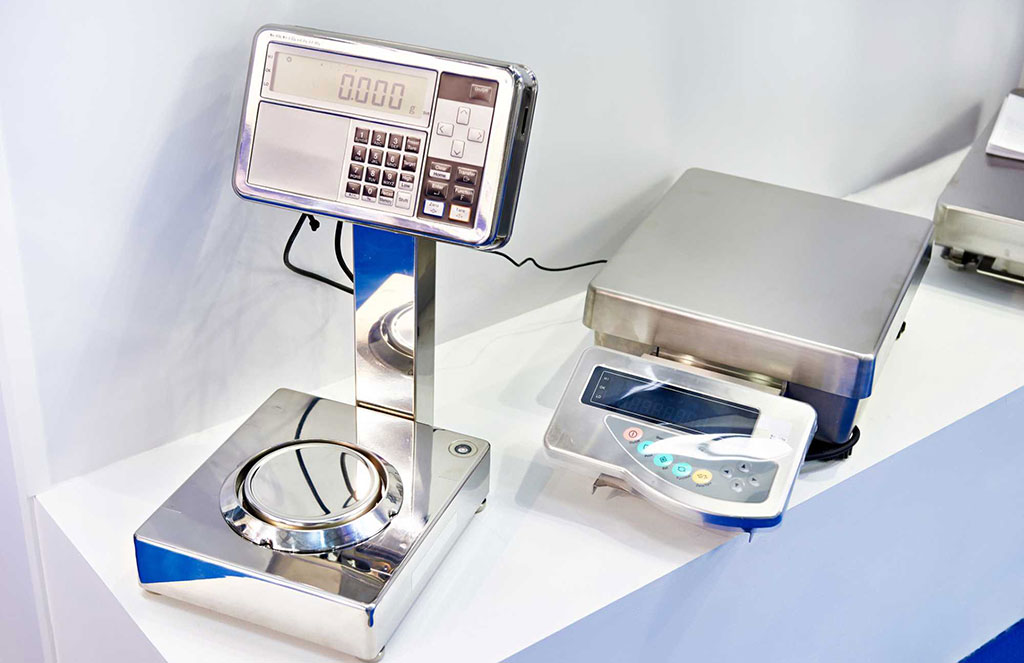

Today’s weighing systems are much more complex than those of a few decades ago. This means more accurate weighing, but also more elements to control and more difficult maintenance.

However, by scheduling regular servicing (and adhering to the relevant intervals), the risk of breakdowns can be significantly reduced.

This is important in order to reduce the maintenance costs of weighing and management systems in general, and to avoid problems related to equipment failure. Preventive maintenance is certainly one of the best solutions for those who want to save on the costs of maintaining their equipment and increase the efficiency of their systems.

The importance of control frequency

To avoid risks and spend less on maintenance, it is advisable to decide on the frequency of checks not only on the basis of system use. Often it is also appropriate to base it on the size of the system. Many modern products are smaller and lighter. They take up little space and can easily be placed in any corner of your operating area.

These compact dimensions are practical and advantageous, but they also mean that even smaller components have to be implemented. These are also often more sensitive to wear and tear and more prone to failure. Programming the frequency of maintenance of weighing systems, also taking this factor into account, will certainly be a good solution.

Maintenance of weighing systems is important, but not only that

Today, many companies are aware that maintenance and repairs are one of the best ways of achieving maximum operational availability of a system.

For this reason, there is an increasing tendency to optimise these operations, in the certainty that good maintenance can avoid production stoppages and unexpected costs.

However, it should not be forgotten that, as well as maintaining weighing systems correctly, it is important to have a high-performance, accurate, robust and high-quality system in the first place. This reduces the expense of maintaining the equipment even further and increases the productivity of your business. Consequently, with a better system you can work better and offer better products to your customers.

AEP transducers products

At AEP transducers we are at the service of your company, with the intent to propose systems of high quality and performance.

With more than 40 years of experience in the field of weight, force, pressure, torque and displacement measurement, we guarantee accurate, innovative, durable and high-tech products.

If you would like to know more about weighing system maintenance and our products, please do not hesitate to contact us.

08

Jan 21Load cells: fields of application and recommendations for use

- 8 January 2021

- Redazione_AEP

- AEP transducers, load cells, measuring weight

Load cells are used in many types of industries and in many situations. In many of these cases, it is important to know how they work and some tips for better use. Today we are talking about them in this short guide: What are the fields of application and tips for the best use of a load cell?

When using the load cell

This device is mainly used to measure the weight of various goods and objects. Therefore, it is useful within many industrial and commercial areas. It is interesting, however, to know that load cells can even be used inside beverage or food vending machines. In these situations, the device is used to sort the packs and make sure that they are all at the same height despite the different weights. In general, the most common fields of application for the cells are as follows:

- Weight measurement of railway wagons, ships or trucks.

- Measurement of the weight of food products for industrial packaging.

- Weight control for checking the quality of goods.

Load cells in the weighing field have different capacities and can measure from micrograms to tons.

The main advice for better use

Most of these devices have specific features and functionalities more or less peculiar. For this reason, before choosing a product of this type and using it, it is necessary to know its properties, operating modes and differences from other similar products.

These characteristics are especially important in terms of how the load cells are used and maintained. For example, some systems need to be cleaned every day and some also withstand particular stress or are able to operate under certain environmental conditions, while others do not. Therefore, it is essential to know in detail the device you are going to use.

Other suggestions not to be underestimated

In order to be sure that the cell can give optimal results, it is good practice to understand its range. It is also advisable to use the appropriate cleaning tools and products and use it only in an environment where it can operate well.

It should also be remembered that the material of which the load cells are made makes all the difference. In fact, for some people it is not recommended to use it in humid environments. For aluminium, on the other hand, it is suggested to avoid difficult weighing. Finally, it should not be forgotten that the preventive maintenance of weighing systems is always the best solution for those who want to save costs and count on the maximum efficiency of the devices.

Where can you find optimal load cells?

The advice we have just shared in this article will help you select the best product for you and make the best use of it. Don’t forget, however, that the support of experts can be very important, especially during the selection process. It will be essential to prefer quality, durable, resistant, precise and functional products.

We at AEP transduscers offer you our many years of experience in the design and production of ATEX-certified measuring instruments and sensors. We can guarantee you individual advice and solutions, as well as the most suitable load cells for your business. Please do not hesitate to contact us for more information.

10

Nov 20Load cells are a necessary tool for those who want to optimise their weighing systems. They are especially important in the industrial sector, where maximum precision and also easier weighing practice must always be guaranteed. They are also very useful in the field of mechanics.

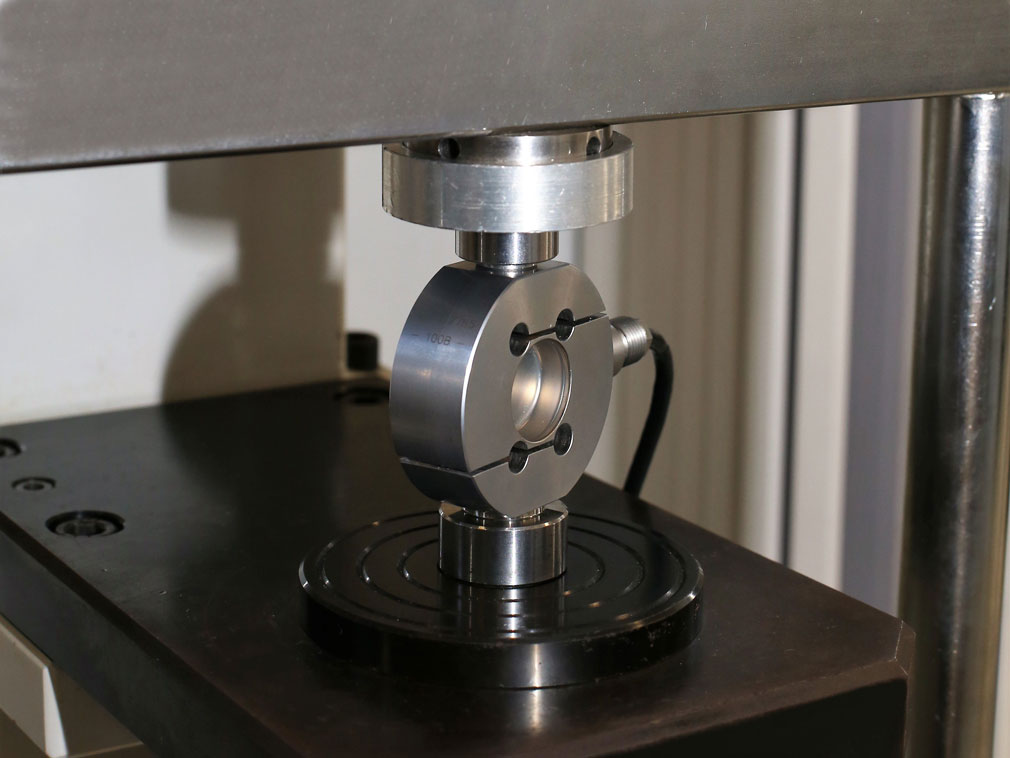

In particular, these instruments are equipped with a strain gauge, a special element capable of understanding the flow rate and the maximum measurable value. Load cells are useful for detecting the possible presence of a mechanical deformation in an object. Let’s go to know some more details about these functional and interesting instruments.

How do load cells work?

As far as the operation of the load cells is concerned, you must bear in mind that these instruments emit a special signal proportional to the weight loaded. This signal is then translated into a real numerical value, made visible directly on a display.

The different types of device

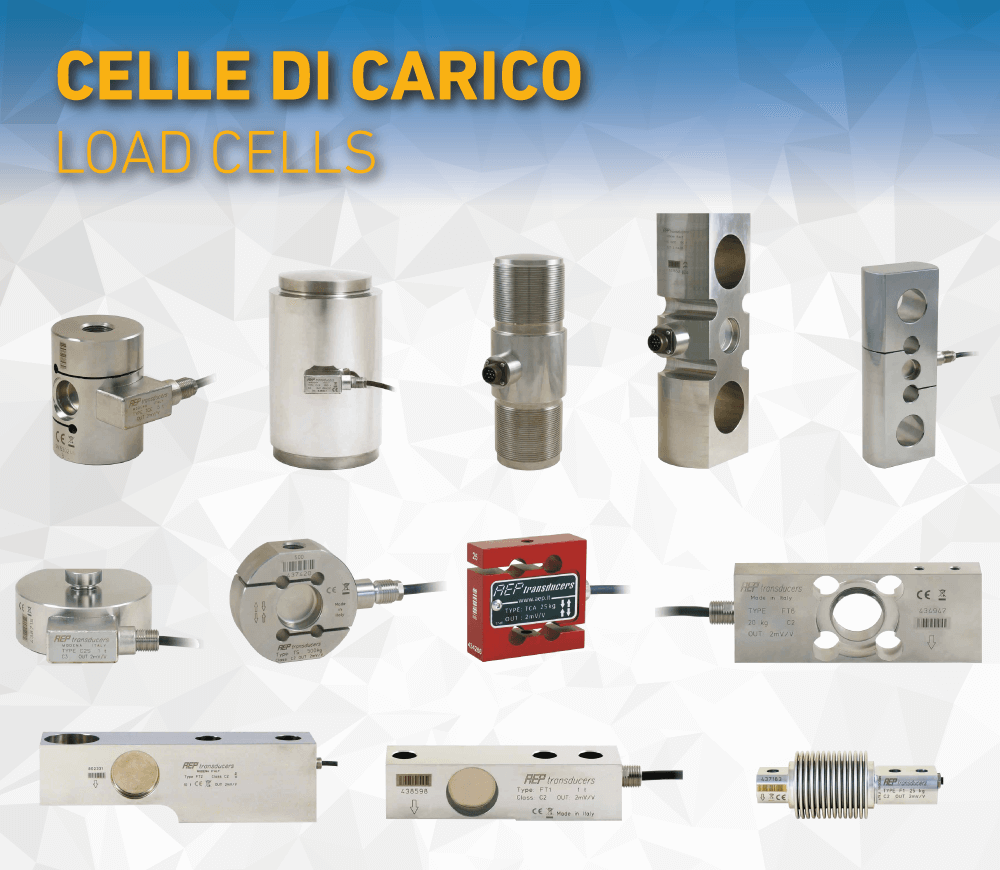

There are many types of load cells available on the market, but the most popular are the electronic ones. However, you can also opt for hydraulic cells, which are perfect in many situations and industrial contexts. Compression cells are the most widely used in the industrial sector, due to their high ease of installation. It is important, however, to bear in mind that this type of cell is not particularly suitable for non-stable loads. The same applies to tension load cells, which are used in all those cases where the load is suspended and/or of large dimensions. There are also double shear cells, considered the most reliable for those who need an instrument capable of guaranteeing greater staticity and precision.

Other types of load cells

Other types of load cells

For those who need a high level of pressure in small loads, the right choice is the bending load cell. Pivot load cells, on the other hand, are more useful for accurately measuring the lifting force, where you may not have a support.

Finally, there are two other types of load cells. One equipped with off-center weighing, which guarantees precise weight even when the load is not located in the centre, and a universal one. The latter is ideal on all those occasions when it is necessary to measure forces in the opposite direction and ensures precise measurement throughout the entire process.

Our load cells

The load cells are part of the instruments and devices that you will find in our catalogue. In fact, we at AEP transducers have been involved in the production of these devices for years. We do this by guaranteeing the production of products that all meet the requirements of the OIML R60 (International Organization of Legal Metrology) standard. This standard establishes all the tests (temperature, humidity, barometric pressure, etc.) that the product must pass in order to fall within certain accuracy classes, such as C2, C3, C4 and more.

To guarantee these requirements to our customers, we have developed automatic direct weight machines, accredited by ACCREDIA in 1996, which are useful for model verification according to this standard. Our load cells are constantly checked during series production in order to guarantee precision and quality, but also continuous product improvement.

20

Aug 205 tips for selecting load cells

- 20 August 2020

- Redazione_AEP

The choice of load cells is an important operation, which we certainly cannot underestimate. Clearly, however, it is not a simple selection: it is necessary to evaluate many details, many needs and relevant characteristics. With this in mind, we would like to share a few tips with you. These are suggestions that will help you make the right choice for these particular transducers.

Tip 1 – Evaluate the environmental conditions

It is vital to identify load cells that are in line with the type of environment in which they will operate. Particular attention must be paid when working in environments with extreme temperatures or excessively humid and/or in the presence of corrosive substances. All these factors influence the choice of load cell type: not all models will be suitable for your working environment.

Tip no.2 – Select the material carefully

Generally, load cells are made of steel, but there are models made of other materials. For example, aluminium is preferred for single point cells. The latter is not particularly performing in very humid environments, let alone in similar contexts or more difficult environmental conditions. For other models, instead, stainless steel is chosen, which is certainly more expensive but much more resistant. It is mainly suitable for those who work in environments where the presence of corrosive chemicals is high.

Tip n.3 – Pay attention to load cell capacity and dimensions

Another aspect you need to focus on is size and range. These details are essential, especially for load cells that have to bear the weight on one side only or have to withstand sudden overloads.

Tip no.4 – Precision is a priority

When choosing such a product, it is essential to carefully assess its accuracy. Thermal errors can also affect the performance of load cells. Therefore it is good to carefully analyze the selected transducer, especially with regard to the quality of the compensation system.

Tip 5 – Attention to detail

Load cells are characterized by a thousand different details and many of them are fundamental for their good functioning. Precisely for these reasons, it is important to choose a model that has everything you need, without being satisfied. There are elements that do not emit vibrations, some more suitable for working indoors or outdoors, in water or in dry environments.

Our conclusions

The advice we have shared within this article may help you make the best choice. Therefore, keep them in mind and use them as soon as the opportunity arises. Don’t forget that in order to select quality products, you can request the support of our team. With our many years of experience in the design and manufacture of ATEX-certified measuring instruments and sensors, we can offer you individual advice and solutions. We will offer you the most suitable load cells to meet your needs and also many other functional and excellent instruments in every respect!

20

Mar 20The main features of our load cells

- 20 March 2020

- seositi

We at AEP transducers have always offered reliable products and high-performance components that fully meet the needs of those who work in the industrial and metrology fields.

Among the many items we design and manufacture, you will find load cells.

Let’s discover in depth the characteristics of these products and the peculiarities of our proposals.

What are load cells?

As you know, load cells are transducers that are able to convert a certain weight, positioned above its axis, into an electrical signal.

The magnitude of the latter will depend on the strain that this force produces on the elastic body of the cell.

These electronic components can be defined more simply as normal elastic metal bodies, to which several strain gauges are added.

By working together, all parts are able to modify their electrical resistance.

Load cells are useful for weighing, measuring and controlling a given force or weight.

In most cases they are applied to scales, vehicle scales, cranes and tanks.

Our load cells

In the specific case of load cells produced by our company, you will find a wide assortment.

First of all, we would like to point out that these electrical components are manufactured directly within AEP transducers and fully comply with the requirements of the regulations in force.

The products offered to you have all passed specific tests for measuring temperature, humidity and barometric pressure. After that they are suitably divided into accuracy classes.

During their production, but above all once the load cells have been manufactured, they are scrupulously checked by the staff of the Metrological Laboratory in charge, in order to always be able to offer customers the best products.

Many products not to be underestimated: a vast assortment for every need

By relying on AEP transducers, you can find the most different load cells, distinguished according to the type of operation.

Among the many types you will find those specifically designed for the measurement of different loads, both static and dynamic, in compression and traction, bending, shear, off center or traction only.

All of them are differentiated according to the type of use, but in particular according to the maximum load they can measure.

Our company AEP transducers

Our company AEP transducers has had a solid presence in the market for over 50 years, especially in the production and sale of load cells and various types of transducers, torque transducers, pressure gauges, dynamometers and application software.

The entire section of the products we manufacture is the result of careful design, designed to ensure the highest quality and reliability.

Despite the continuous evolution of the world of technology, our reality has always managed to perfect itself and so today is able to offer you articles with the highest innovations not only in the industrial field, but also in the metrological field. For these reasons, AEP is classified as a completely hi-tech company.

You can rely on us to obtain a valid supply of load cells and other components, but also a personalized advice able to offer you diversified and optimal solutions from every point of view.

Other types of load cells

Other types of load cells