06

Apr 21Force transducers: Piezoelectric sensors or strain gauge sensors?

- 6 April 2021

- Redazione_AEP

- force transducers, Piezoelectric sensors, Strain gauge sensors

When it comes to force transducers, two principles of operation are most frequently used: those based on the use of piezoelectric sensors and those based on the capabilities of strain gauges. Which are the best? It is more appropriate to say that in certain situations and in specific contexts one type of sensor is more appropriate than the other. So let’s get to know them in more detail. This will help you to understand which is the best solution in your case.

The main features of piezoelectric sensors

Piezoelectric sensors, which are used for force transducers, generally consist of two discs with a foil electrode between them. When a certain force is applied to these devices, an electrical charge is immediately generated. This charge is measured by a charge amplifier. In other words, the charge generated is directly proportional to the force that is applied to the transducer, and the amplifier enables the force to be measured.

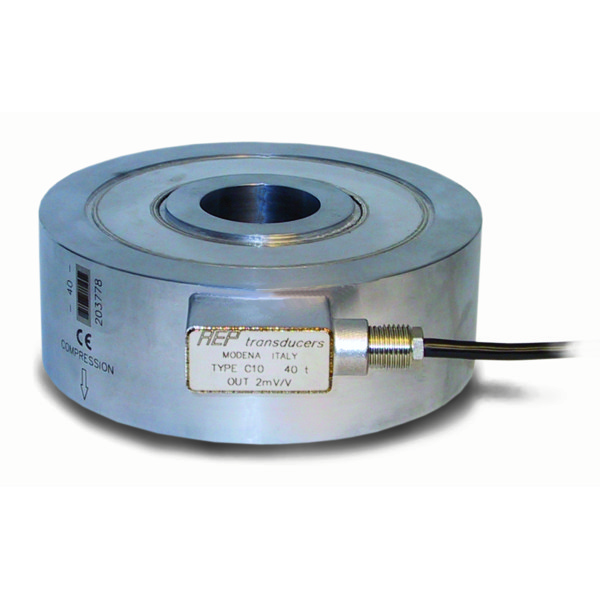

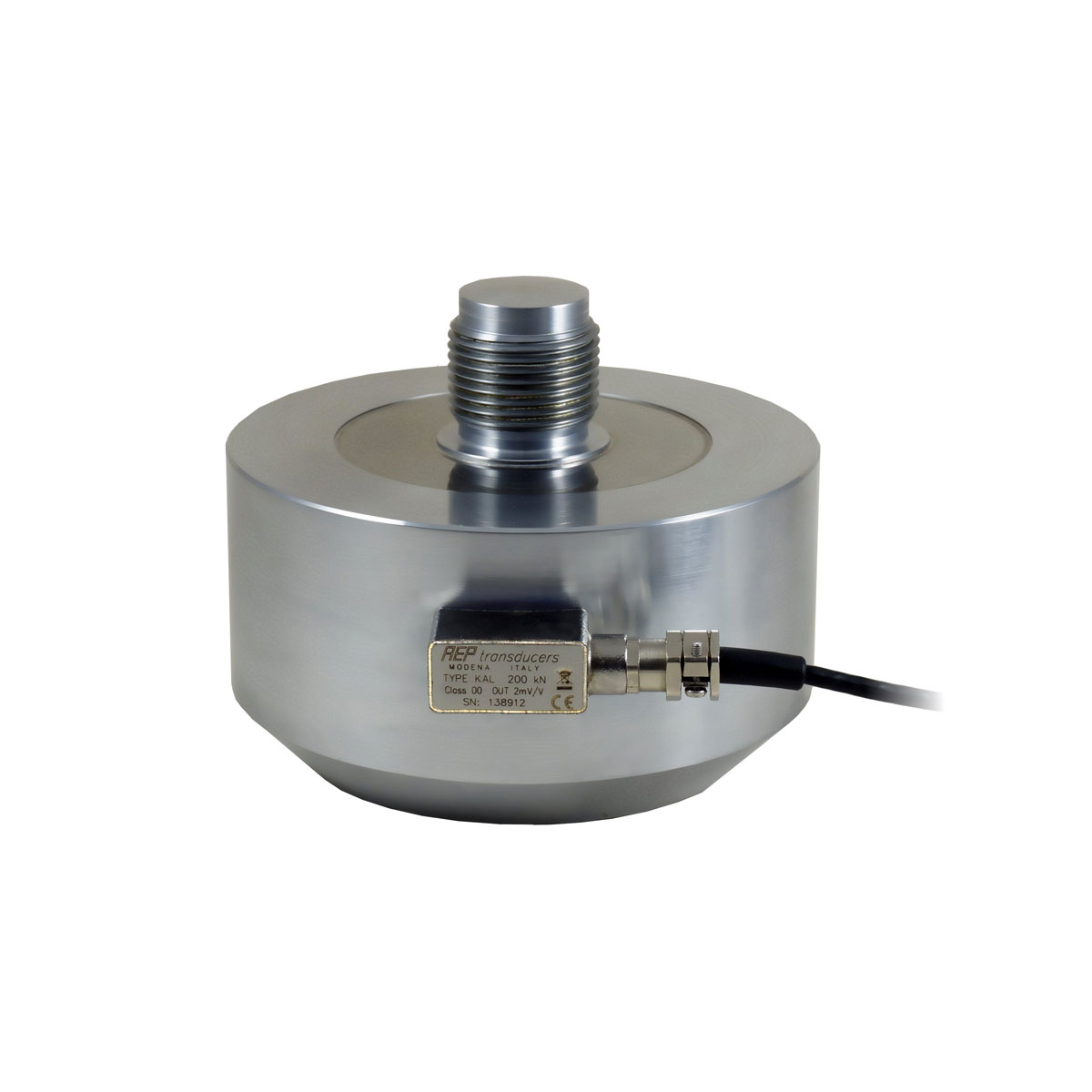

Force transducers with strain gauge sensors

A strain gauge sensor allows force to be measured in a different way. It always contains an element made of a strong, elastic material on which force is applied. This force clearly causes a slight deformation of the spring element, by which the applied force can be measured. Depending on the size of the spring element, the measuring range of the device can be determined.

Which sensor to choose?

In most cases, force transducers with piezoelectric sensors are the best choice if you are looking for an element that offers high stiffness. Consequently, they are even suitable for those who also want a high resonance frequency. Systems using a strain gauge sensor, on the other hand, have a relatively low resonance frequency.

In general, the choice of piezoelectric sensors is ideal for those who need to measure small forces quickly. Strain gauge operation is the best solution for those who need to measure large forces.

Support from professionals

Even those who have been using force transducers for a long time can benefit from the support of professionals. It is a good idea to get help from the companies that supply and, even better, manufacture these devices. Depending on the machinery, the working environment, the production methods, the specific needs and preferences, the experts can recommend the best sensor for the customer.

They can provide products suitable for even the harshest environments, such as IP68-rated force transducers and/or protective housings. Finally, professionals in the field can offer customised advice and a variety of solutions for those looking for high precision requirements as well as value for money.

Force transducers and sensors from AEP transducers

AEP transducers offers modern and efficient force transducers and sensors with the best metrological characteristics. Our laboratory is always working to ensure accurate, functional, robust and state-of-the-art products. We look forward to offering you customised solutions that are perfect for your working environment.

23

Feb 21Not everyone is familiar with the pressure sensor. Despite this, it is useful to say that we have a fundamental and widely used instrument which is of great importance in certain sectors. It is used in industries and laboratories of various types. But what are its characteristics? Let’s see what it is and what this instrument is used for.

What is a pressure sensor?

A pressure sensor is an analogue instrument which can be used to measure an important piece of data: the pressure exerted by a liquid or gas inside a machine. In the industrial sector, many machines use the pressure exerted on a certain element to facilitate certain production processes. Therefore, the sensor can allow useful modifications to be made to prevent potentially harmful situations within the company or to optimise production activities.

What this sensor is used for and why it is important

As already mentioned, this device is used to improve the use of certain machines and, more specifically, to assess the levels of pressure exerted on a given element. In some cases, in fact, a specific level of pressure is needed to promote the correct operation of a particular piece of equipment. With the pressure sensor, it is clearly possible to keep these levels under control, avoiding damage, unforeseen events and production slowdowns, and promoting better performance of daily work.

To be more specific, it should be noted that in some cases it is not possible to exceed a certain pressure level when using a machine. Thanks to the appropriate sensor, you can know in real time if the limit has been exceeded. Therefore, you have the opportunity to intervene manually and promptly, precisely to prevent any damage from affecting the entire instrument.

Finally, it is important to consider that a pressure sensor also makes it possible to understand when the machinery in question is not being used properly. Perhaps it needs a different pressure than the one being measured. Thanks to the sensor, it is possible to intervene and fully optimise the functions of the equipment in your possession.

Pressure sensor: our conclusions

As we can see, the sensor in question can take on great significance within a company, proving to be indispensable, to say the least. It allows you to monitor the functionality of your machinery and optimise its performance on a day-to-day basis. It also helps to avoid potentially negative situations and allows you to operate in a safer environment. All this is very important for modern companies, always looking for functional and innovative solutions, quality and efficiency in every aspect.

AEP transducers has an established presence on the market for the design, production and sale of strain gauge sensors and pressure transducers, electronic instrumentation and application software. Within our catalogue you will find many quality products, suitable to promote a better functioning of your machinery. Our laboratory is always working to guarantee precise, functional, durable and state-of-the-art products. We are therefore at your disposal to offer you more information on the pressure sensor and much more. We look forward to offering you customised solutions that are perfect for your working environment.

10

Feb 21Our company has been producing accurate, functional and quality strain gauge sensors for many years. Therefore, over the years we have analysed numerous solutions and followed the progress of technology step by step. With this in mind, we would like to share some of our knowledge with you today by telling you about the difference between electrical and optical strain gauge sensors.

Let’s start with the basics: what is a strain gauge sensor?

In order to optimally evaluate and measure mechanical forces, numerous calculations need to be made. Fortunately, nowadays we can rely on various technologies and, more specifically, on the functionality of different strain gauge sensors. Strain gauges allow force to be measured by means of an element made of a strong elastic material inside the sensor.

The force is applied to this element. Of course, this causes a slight deformation of the spring element, through which the applied force can be measured. Depending on the size of the spring element, the measuring range of the device in question can be determined.

Electrical strain gauges

Electrical strain gauges are based on one of the most proven technologies in the industry. They ensure the acquisition of correct values by measuring the change in electrical resistance in a given component. For these reasons, they are excellent for experimental stress analysis or for manufacturing transducers.

In addition, electrical strain gauge sensors are very popular because they can measure mechanical strain by means of films integrated in a load cell or force transducer. In order to acquire a positive or negative strain, a change in the electrical resistance of the strain gauge in question is required.

This type of product is available in a number of different models, which offer various measurements, such as linear strain measurement in a single axial plane.

Optical strain gauge sensors

Optical strain gauges use the properties of light and an optical fibre to measure mechanical strain. They consist of silicon optical fibres, coated with robust polymers, and Bragg fibre. This combination improves the performance of strain gauge sensors.

The Bragg fibre is placed in the core of the optical fibre: these two components allow light to pass through the grooves and be reflected back through the bandgaps. Variations of the periods of the Bragg fibre are normally given by mechanical deformations, which cause variations of the light.

Finally, there is an interrogator connected to the optical fibre, which can scatter laser light of various wavelengths and analyse the reflected light via the optical sensor. The optical sensor measures the various mechanical deformations.

Which strain gauge sensors are suitable for your company?

If you have doubts about which product to implement in your daily work, we suggest you evaluate the solutions of AEP transducers. We offer modern and efficient strain gauge sensors with the best metrological characteristics. We are available to answer your questions and to guarantee accurate, functional and customized products.

25

Jan 21Thanks to various studies and advances in the field of technology, for some time now we have had different types of transducers available. Today we are talking about force, displacement and pressure transducers. What are their characteristics?

A brief introduction to these interesting devices

Before going into detail, it is useful to say that a transducer is a particular device capable of converting a given physical quantity into another. In practice, it receives an input signal and proposes another at the output. Some transducers are also capable of transforming one type of energy into another.

Characteristics of force transducers

Force transducers are sensors that transmit the force itself in a different magnitude or change only some of its characteristics. They are used in various sectors, both in industry and in more common applications. There are basically two types of force transducers: homogeneous force transducers and non-homogeneous force transducers, also called “hybrids”.

Pressure and displacement transducers fall into the category of force sensors. This is because pressure is defined as a force per unit area.

Displacement transducers

Displacement transducers are also called “displacement sensors”. They prove to be instruments which ensure that the results of calculations in certain areas of research and development are correct. All transducers of this type operate on the principle of inductive measurement.

They are easy to use, compact and robust, and offer high levels of accuracy. They also tend to wear out slowly. A displacement sensor can be used for a variety of purposes: from high-precision measurements in the micrometre range to simple monitoring in production.

Pressure transducers

A pressure transducer converts the pressure it receives as input into an analogue electrical signal. This conversion is triggered by the deformation of the strain gauges inside the device. In practice, the applied pressure deforms the strain gauge, which then changes its electrical resistance in proportion to the pressure. Again, these are instruments that, if chosen carefully, operate independently, functionally and accurately, and can last a long time.

What is the ideal transducer? AEP transducers solutions

Choosing the right transducer for your business may not be as simple as it may seem at first glance. That’s why we at AEP transducers stand by our customers and offer comprehensive and personalised support. Thanks to our many years of experience, we guarantee the design and manufacture of quality, tested and certified transducers.

We offer a wide range of force, displacement and pressure transducers. Our solutions are reliable, functional, efficient and durable. With this in mind, we invite you to put us to the test. Contact us as soon as possible for more information and advice tailored to your needs and preferences.

24

Nov 20The use of pressure transducers: characteristics and solutions to consider

- 24 November 2020

- Redazione_AEP

- pressure transducer maintenance, pressure transducers

Today we are talking about the use of pressure transducers, fundamental instruments in certain sectors, which have a very precise objective: to improve the use of water, gas and various fluids. Let’s go into detail and see what the main features of these important devices are.

What is a pressure transducer for?

This particular instrument is of fundamental importance in all those sectors where liquids and various types of fluids are used. The instrument in question is used to measure the force of the pressure exerted by these fluids while they are under stress.

Certain machines operate only and exclusively when this value reaches a certain level. For this very reason, it is important to use pressure transducers. They allow you to assess whether you need to apply more or less pressure and ensure that that level can be reached without risking damage to the machinery.

Pressure transducers: how do they work?

As far as the operation of pressure transducers is concerned, it is important to take into account the fact that this instrument is equipped with a particular sensor, which can be fine or coarse-pointed. Depending on the type of fluid used, it will be necessary to use a different tip, which can guarantee less or greater precision.

This sensor must be positioned at the exact point where the fluid is to be measured. Subsequently, you will notice that the sensor will record the pressure. The detected value will then be made known by means of an electromagnetic pulse.

Maintenance operations to consider

It is useful to know that pressure transducers need to be serviced regularly. This will allow you to always have a high-performance instrument at your disposal, capable of ensuring the recording of correct values. Therefore, when purchasing and implementing the transducer, it is advisable to find out how and at what intervals the necessary maintenance should be carried out.

Our transducers, ideal for your business

If you need to keep the pressure of a fluid under control during your production processes and want to prevent a machine from actually being damaged, you should certainly use this tool. You can select pressure transducers directly from our catalogue.

We have been involved in the design and production of this type of device and many others for years. Our pressure transducers range from 100 mbar to 2500 bar. We offer versions for relative, absolute, vacuum and differential measurements, amplified and non-amplified, with an accuracy class from 1.0% to 0.05%.

We are waiting for you to guarantee you diversified and quality solutions

Our products guarantee high reliability every time, thanks to our production processes and careful selection of raw materials. We use precise instruments able to guarantee the production of high performance products from every point of view.

Precisely for these reasons, we serve customers all over the world, who rely on our precision and our technical solutions for different types of business. Do not hesitate to ask us for more information about pressure transducers and more.

19

Oct 20Ours is a company that designs, designs and sells technologically advanced products. Nowadays, our presence on the market has been consolidated, in particular in the design, production and sale of strain gauge sensors, electronic instrumentation and application software. Starting from this assumption, today we are talking about the production processes of AEP transducers.

The quality and main characteristics of our production

In order to continue to have an increasingly important position on the international market, our company has decided to devote a good part of its investments to an increasingly advanced type of automation. Therefore, our production cycles are innovative, fast, intelligent and functional. This allows us to always guarantee an excellent quality-price ratio to all our customers.

The production processes of AEP transducers are accompanied by careful control of raw materials. This is a fundamental process during the production phase of our products, which usually takes place through some metallographic analysis of the steels used.

The technology that accompanies our production step by step

During the production phase, our company uses heat treatments. These treatments are carried out with ovens equipped with really advanced technologies, which allow us to confirm our products with decidedly optimal characteristics.

AEP transducers’ production processes also require the company’s technicians to apply strain gauges to the sensors in production every day. This enables AEP to guarantee the highest levels of performance and therefore high quality devices. Subsequently, the sensors in production are hermetically sealed through the use of highly technological and computerised systems. These take care of welding the various components using a laser that works continuously and pulsed. This operation makes it possible to offer products with great stability and durability.

Other details concerning the production processes of AEP transducers

Our production activities require the sensor to be identified by a number printed in series with laser marking. This allows the sensor to be tracked during each stage of the production process.

Our sensors are individually calibrated with samples loaded twice as much as they usually are, so that both mechanical and electrical resistance can be effectively assessed. In the end, the sensors produced by AEP transducers are compensated using an automatic climate chamber. The electronic circuits are assembled using automatic machines and then tested one by one.

Our production is at the service of various operating sectors

As you have noticed, during AEP transducers’ production processes, nothing is left to chance. By the way, this is just a summary of what we do in our laboratory. We are well aware that production is the fundamental part of a company’s life. Therefore, we do everything we can to make it perfect in every respect. This allows us to respond skilfully to the needs of all those involved in electronic weighing and dosing. Our products are suitable in the field of automation; in research, calibration and testing laboratories; and in the hydraulic, oil-hydraulic, automotive and other industries.

08

Oct 20Are you looking for a quality torque meter? If you answered yes, you have every reason to do so. In fact, we are dealing with a useful and almost indispensable tool in many areas. However, it is always important to use a precise and high quality product in order to benefit from good performance. Therefore, let’s get to know the characteristics of a quality torque transducer: with the right awareness you can make the right choice for you. Afterwards, we will offer you some interesting solutions that are suitable for all kinds of needs.

The torque transducer identikit

Also called several times “torque meter”, the torque transducer is a device able to instantly detect the measurement of the torsional deformation of a shaft that is subjected to two different opposing forces. These forces are usually generated by a motor and a brake. From this it can be seen that the torque transducer is a very useful instrument in different fields: it is used in different types of industries and sometimes also in everyday life.

The industry market offers many different solutions. For example, it is possible to choose a mechanical or electronic device. There are also optical and strain gauge torque transducers. The latter is currently the most widely used variant together with the electronic one.

But what should a quality torque transducer look like?

In order to have a functional and high-performance product, it is important to rely on valid and specialized manufacturers. They can guarantee precise and reliable devices first and foremost. They will also be able to provide highly resistant and long-lasting products, precisely because they are made of robust and wear-resistant materials.

The best torque transducers on the market are those belonging to the accuracy classes from 0.03% to 0.20%. Most of the most qualitative devices are characterized by compact shapes and dimensions and have many technical features not to be underestimated. Among these, however, it is always advisable to look for products with optimal nominal charges and valid calibration systems.

In search of the ideal torque transducer

As anticipated, in order to use a functional and performing product, it is advisable to rely on valid and specialized manufacturers. With these assumptions, we invite you to view our solutions: AEP transducers takes care of the design, production and sales of these instruments and many others. We guarantee quality, a wide choice and many different solutions for the most varied requirements.

Specifically, we offer a wide range of dynamic and static torque transducers with accuracy classes from 0.03% to 0.20%. Our technicians can manufacture torque transducers of different types and sizes, i.e. to suit your needs. We ensure high quality standards and devices able to provide fast and accurate measurements every time.

Our consulting and customized solutions

Even when it comes to purchasing a torque transducer, you can therefore count on AEP transducers. Depending on your needs, we will offer you detailed advice, but also reliable and durable products that will optimize your daily work activities. We look forward to offering you our comprehensive support, as well as the production and design of efficient and state-of-the-art instruments.

24

Sep 20Industrial electronic instrumentation: our products

- 24 September 2020

- seositi

Finding the perfect industrial electronic equipment for your company is not always easy. For this reason, we at AEP transducers have developed different solutions. In this way we can respond to different needs and help various realities to optimize their daily work activities.

Transmitters, receivers and digital indicators: here are some of our proposals

By viewing the section of this site dedicated to industrial electronic instrumentation, you can evaluate many efficient, versatile and quality products. Among them you will find the professional wireless transmitter WIMOD, suitable for force, weight, pressure, torque and displacement measurements. You can apply it directly to the sensor body or use it in stand alone mode. Through a special integrated communication system, the instrument can interface in real time with PCs, tablets and other electronic devices, proving to be highly functional.

Another of the products in our catalogue related to industrial electronic instrumentation is the DYNAMICSTAR. The latter is a valid handheld indicator. It is professional, ergonomic, extremely versatile and very easy to use in terms of weight, force, pressure, torque, speed, angle, power and displacement measurements. It is excellent for static as well as dynamic applications. It is equipped with an internal data logger and many features not to be underestimated.

Our electronic instrumentation also includes many receivers and many other handheld transmitters and indicators for the various measurements of force, weight, pressure, depression, etc..

Our products: from design to production

Our team offers not only the sale of the various devices. On the contrary, we also take care of every step of the realization, from the design to the production of electronic instrumentation for measurements of weight, force, pressure, torsion, displacement, etc..

Inside our company we develop efficient and advanced instrumentation, guaranteeing products suitable for the optimization of industrial applications and weighing systems. Many of our devices are also suitable for implementation in calibration laboratories, test laboratories, research laboratories and many other similar facilities.

Common features in all our products

As you will notice once you get to the page dedicated to industrial electronic instrumentation proposed by AEP transducers, we offer a wide range of products suitable for all needs. In any case, we guarantee high standards of quality, accuracy and precision, versatility and practicality of use. Our products are state-of-the-art and equipped with the latest technology. All the electronic circuits used are assembled internally on automatic machines of the latest generation and are tested individually.

These are the common features of all our devices. Clearly, each of them has its own technical specifications, which you can see in the relevant product sheets

To make use of a valid electronic instrumentation, do not hesitate to ask for our support

With this in mind, if you are looking for quality industrial electronic instrumentation, please do not hesitate to contact us. Our aim has always been to provide every industry with diversified and quality solutions. We look forward to providing you with efficient devices and individual advice according to your specific preferences and needs.

10

Sep 20Many ways to make the best use of a dynamometer

- 10 September 2020

- Redazione_AEP

The dynamometer is a very useful tool, at industrial level and not only. What are its uses? In this guide, we will explain how to use it in the best possible way, also indicating some interesting solutions. Let’s start with the basics.

What is a dynamometer?

For those who approach the use of a dynamometer for the first time, it is useful to know that it is an instrument that is used to know the intensity of a force or weight. There are both digital dynamometers and more traditional instruments: in any case, their operation is based on the presence of a spring that extends. In relation to its elongation, the tensile force or weight is determined if the force corresponds to that of gravity.

The difference between digital and mechanical devices lies in the fact that the former can read the value through a display, usually LED or LCD. In the second case, instead, the value will be read on a graduated scale. The units of measurement will be Newton or kilogram.

The main uses of the dynamometer

The dynamometer is a device that can be used in shops, warehouses, industries and sometimes even in homes. For industrial use, for example, it can measure the weight of large suspended loads. Even adapters can be used in such contexts. These enable the device to measure not only the tensile force but also the compressive force.

In domestic use, the dynamometer is useful for weighing travel cases and other similar uses. It is relevant to consider that this instrument can also be used in the medical field, both in diagnostics and to determine the muscle strength of an individual. The latter is an important operation in particular to assess the effectiveness of rehabilitation.

Specific uses of the dynamometer

Specific uses of the dynamometer

In addition to the more “classic” uses, this tool can be a valuable ally in many other situations. For example, it can be used if you want to make sure that the straps used to hold the tarpaulins of vans are tightened effectively. In fishing, a dynamometer can be used to assess the strength of the threads inserted on the rod. It is no coincidence that there are special instruments for making these measurements on nylon threads.

In the textile sector, this instrument is indispensable: it enables the strength of the fibres to be measured and their breaking point to be assessed. Also in this case, specific dynamometers for the textile sector are available on the market. It is also possible to use the instrument in the context of archery. Each bow, in fact, has a specific poundage, which indicates the amount of force required to tension the bow. To measure it, it is sufficient to use a dynamometer that indicates the peak of power.

Dynamometers for industry and beyond

In short, as you will have understood, the dynamometer is a very useful tool. In our online catalog you can find it in various models, useful to meet every need and preference. We invite you to view them as soon as possible, together with our other products, and contact us to get all the information you need.

02

Aug 20As you well know, most of the more “traditional” work instruments, and used since the past, still exist. However, these instruments have evolved, becoming “modern”. The pressure gauge has also seen a sort of evolution over the years, and today we gladly use digital pressure gauges.

We at AEP transducers are involved in the design, production and sale of these very useful instruments in various fields. By putting our experience at your disposal, today we talk about the main features of an excellent and efficient digital pressure gauge.

What is a pressure gauge?

Before we begin, we certainly need a little introduction. Therefore, it is useful to say that we are dealing with an instrument that, in its classic version, thanks to a mechanical system can measure the pressure of a fluid. Currently, it is possible to obtain the same measurement using a digital instrument. However, in order to benefit from excellent performance, it is necessary to use a digital pressure gauge of remarkable quality.

What are the main features of a quality digital pressure gauge?

Before buying a product of this type, it is essential to be absolutely certain that it can work extremely accurately. Manufacturers must therefore guarantee a minimum error rate. In order to choose the right pressure gauge, it is therefore possible to evaluate the reviews, the price and the level of reliability of the company. If only the latter factor is taken into account, you will be able to make a safe purchase that guarantees precision and quality.

Among the other features that a good digital pressure gauge should have are the display. It seems trivial, but if this was not large enough and clear enough, the proposed results could be unreadable. In practice, the product would be useless. In this case, you should evaluate the product according to your specific needs and preferences. Finally, we must not forget the importance of practicality of use: an efficient tool is also a versatile and user-friendly tool.

The materials that make the difference between an excellent and a poor quality manometer

Needless to say, an optimal digital pressure gauge should be made of robust, durable and durable materials. It goes without saying that this requirement is synonymous with quality. Among other things, it is a feature that will allow the instrument to be used for a long time and on several occasions. A good pressure gauge is highly resistant to high and low fluid temperatures and, of course, also to the highest pressure.

The different types of digital pressure gauge

Once you understand what characteristics to look for when choosing a digital pressure gauge, it is useful to consider that there are different types of this product on the market. They may differ from each other due to particular additional functions and their specific use. You can find numerous solutions within our portal.

As anticipated, in fact, AEP transducers deals with the design, production and sale of digital pressure gauges from 100 mbar to 3000 bar. In the dedicated section you will find many versions for relative, absolute, vacuum and differential measurements. You can view products with an accuracy class from 0.5% to 0.05% and able to guarantee high resolution and high reliability. Do not hesitate to contact us for further information.

- 1

- 2

Specific uses of the dynamometer

Specific uses of the dynamometer