The maintenance of weighing systems: tips to save money and avoid any kind of risk

02

Apr 21The maintenance of weighing systems: tips to save money and avoid any kind of risk

- 2 April 2021

- Redazione_AEP

- AEP transducers Maintenance of weighing systems weighing systems

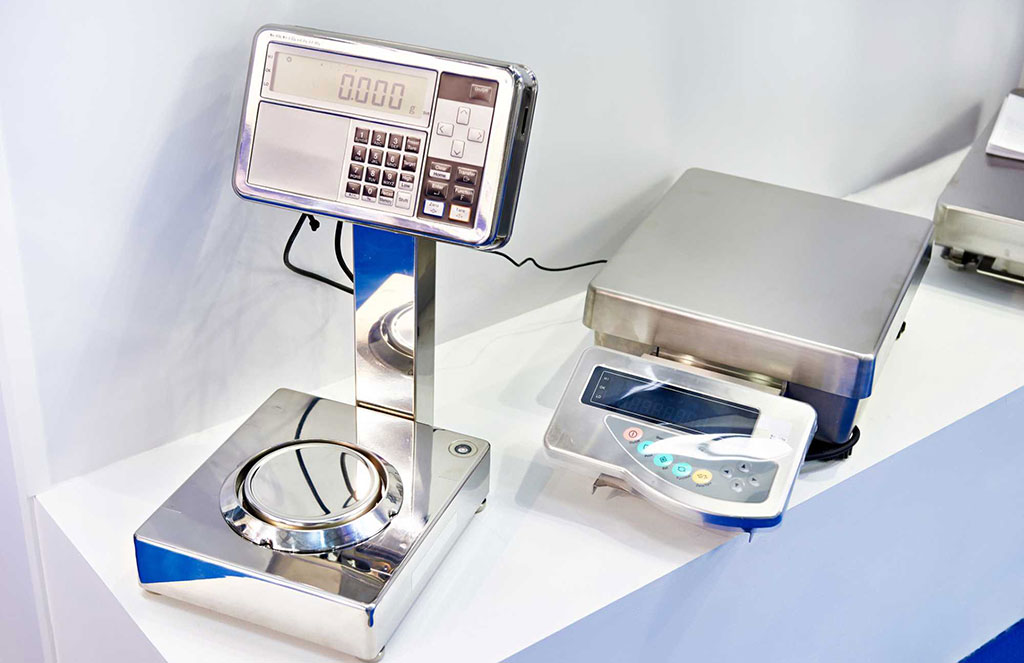

Maintenance is an important operation in every case and in every sector. The maintenance of weighing systems is also important, especially in an industrial environment. If it is carried out correctly, it allows you to operate safely and maintain productivity and the quality of your products. With this in mind, let’s take a look at some tips that can help you save money and avoid any risks, simply by carrying out proper maintenance.

Preventive maintenance to reduce costs and increase system efficiency

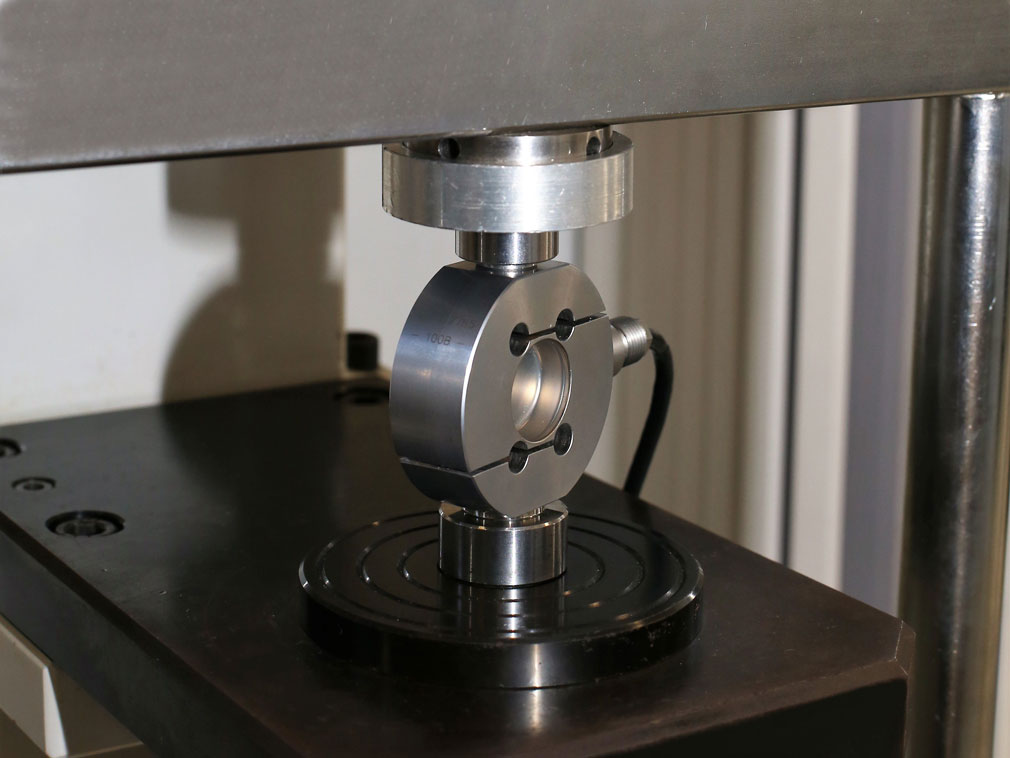

Today’s weighing systems are much more complex than those of a few decades ago. This means more accurate weighing, but also more elements to control and more difficult maintenance.

However, by scheduling regular servicing (and adhering to the relevant intervals), the risk of breakdowns can be significantly reduced.

This is important in order to reduce the maintenance costs of weighing and management systems in general, and to avoid problems related to equipment failure. Preventive maintenance is certainly one of the best solutions for those who want to save on the costs of maintaining their equipment and increase the efficiency of their systems.

The importance of control frequency

To avoid risks and spend less on maintenance, it is advisable to decide on the frequency of checks not only on the basis of system use. Often it is also appropriate to base it on the size of the system. Many modern products are smaller and lighter. They take up little space and can easily be placed in any corner of your operating area.

These compact dimensions are practical and advantageous, but they also mean that even smaller components have to be implemented. These are also often more sensitive to wear and tear and more prone to failure. Programming the frequency of maintenance of weighing systems, also taking this factor into account, will certainly be a good solution.

Maintenance of weighing systems is important, but not only that

Today, many companies are aware that maintenance and repairs are one of the best ways of achieving maximum operational availability of a system.

For this reason, there is an increasing tendency to optimise these operations, in the certainty that good maintenance can avoid production stoppages and unexpected costs.

However, it should not be forgotten that, as well as maintaining weighing systems correctly, it is important to have a high-performance, accurate, robust and high-quality system in the first place. This reduces the expense of maintaining the equipment even further and increases the productivity of your business. Consequently, with a better system you can work better and offer better products to your customers.

AEP transducers products

At AEP transducers we are at the service of your company, with the intent to propose systems of high quality and performance.

With more than 40 years of experience in the field of weight, force, pressure, torque and displacement measurement, we guarantee accurate, innovative, durable and high-tech products.

If you would like to know more about weighing system maintenance and our products, please do not hesitate to contact us.