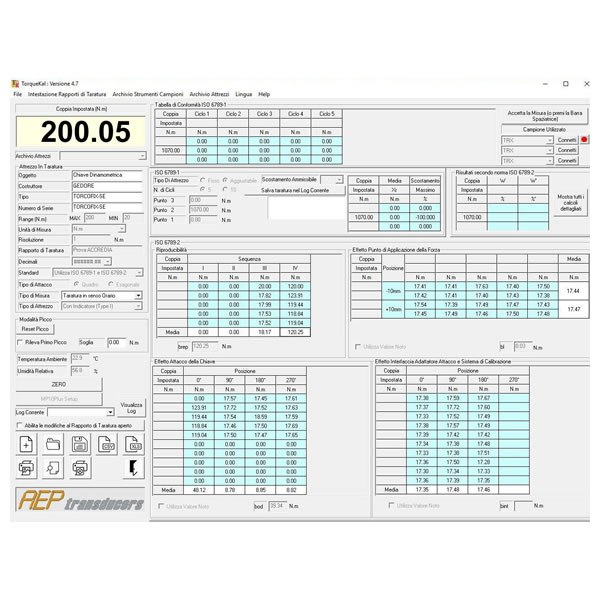

Calibration consists of carrying out five measurements for each torque point calculated normally at 20%, 60% and 100% of the maximum torque value of the device being calibrated.

At the end of the test, the programme calculates, for each measurement point

a) the Average of the readings

b) the % Deviation

c) the Extended Uncertainty %.

All the certificates are then printed and stored in a database to keep a record of the calibrations performed.

The programme manages a further database of Sample Instruments type BTR2 and MP10 connected to the PC via USB communication to guarantee measurement acquisition.

For each Sample Instrument, it is necessary to enter all the identification data, the ACCREDIA certificates or equivalent reference certificates and to enter the various uncertainties subdivided for the various torque points.

The programme automatically manages the expiry of the certificates, notifying the Operator if the certificate has expired.

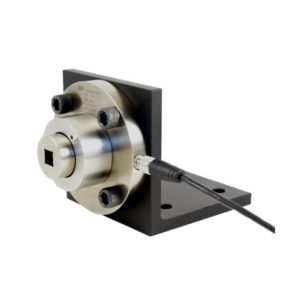

ACCESSORIES

See instrumentation and connection cables