02

Apr 21Maintenance is an important operation in every case and in every sector. The maintenance of weighing systems is also important, especially in an industrial environment. If it is carried out correctly, it allows you to operate safely and maintain productivity and the quality of your products. With this in mind, let’s take a look at some tips that can help you save money and avoid any risks, simply by carrying out proper maintenance.

Preventive maintenance to reduce costs and increase system efficiency

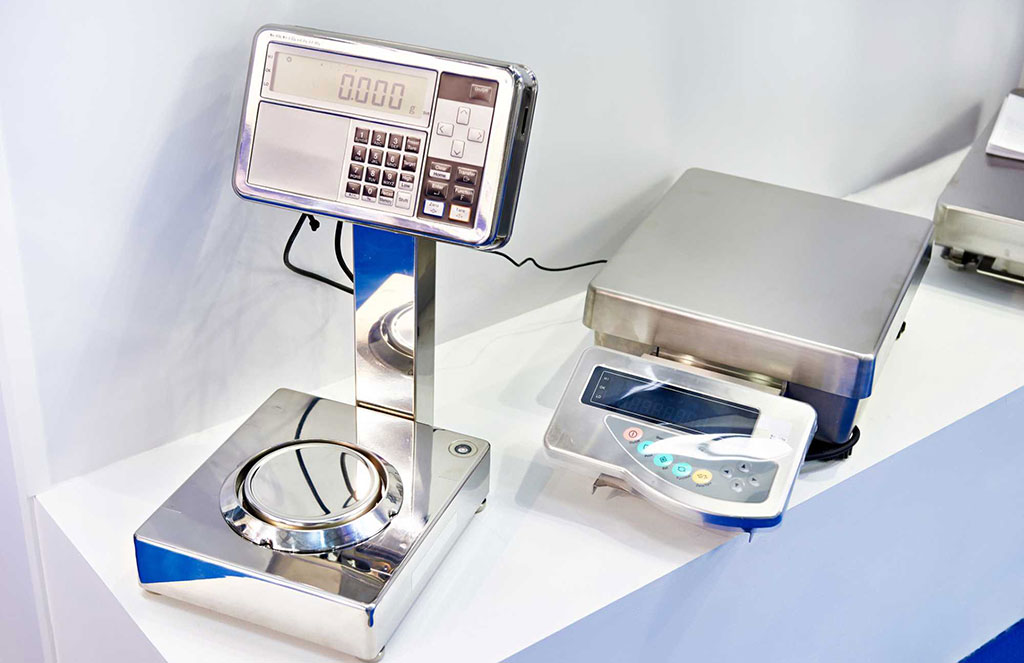

Today’s weighing systems are much more complex than those of a few decades ago. This means more accurate weighing, but also more elements to control and more difficult maintenance.

However, by scheduling regular servicing (and adhering to the relevant intervals), the risk of breakdowns can be significantly reduced.

This is important in order to reduce the maintenance costs of weighing and management systems in general, and to avoid problems related to equipment failure. Preventive maintenance is certainly one of the best solutions for those who want to save on the costs of maintaining their equipment and increase the efficiency of their systems.

The importance of control frequency

To avoid risks and spend less on maintenance, it is advisable to decide on the frequency of checks not only on the basis of system use. Often it is also appropriate to base it on the size of the system. Many modern products are smaller and lighter. They take up little space and can easily be placed in any corner of your operating area.

These compact dimensions are practical and advantageous, but they also mean that even smaller components have to be implemented. These are also often more sensitive to wear and tear and more prone to failure. Programming the frequency of maintenance of weighing systems, also taking this factor into account, will certainly be a good solution.

Maintenance of weighing systems is important, but not only that

Today, many companies are aware that maintenance and repairs are one of the best ways of achieving maximum operational availability of a system.

For this reason, there is an increasing tendency to optimise these operations, in the certainty that good maintenance can avoid production stoppages and unexpected costs.

However, it should not be forgotten that, as well as maintaining weighing systems correctly, it is important to have a high-performance, accurate, robust and high-quality system in the first place. This reduces the expense of maintaining the equipment even further and increases the productivity of your business. Consequently, with a better system you can work better and offer better products to your customers.

AEP transducers products

At AEP transducers we are at the service of your company, with the intent to propose systems of high quality and performance.

With more than 40 years of experience in the field of weight, force, pressure, torque and displacement measurement, we guarantee accurate, innovative, durable and high-tech products.

If you would like to know more about weighing system maintenance and our products, please do not hesitate to contact us.

23

Feb 21Not everyone is familiar with the pressure sensor. Despite this, it is useful to say that we have a fundamental and widely used instrument which is of great importance in certain sectors. It is used in industries and laboratories of various types. But what are its characteristics? Let’s see what it is and what this instrument is used for.

What is a pressure sensor?

A pressure sensor is an analogue instrument which can be used to measure an important piece of data: the pressure exerted by a liquid or gas inside a machine. In the industrial sector, many machines use the pressure exerted on a certain element to facilitate certain production processes. Therefore, the sensor can allow useful modifications to be made to prevent potentially harmful situations within the company or to optimise production activities.

What this sensor is used for and why it is important

As already mentioned, this device is used to improve the use of certain machines and, more specifically, to assess the levels of pressure exerted on a given element. In some cases, in fact, a specific level of pressure is needed to promote the correct operation of a particular piece of equipment. With the pressure sensor, it is clearly possible to keep these levels under control, avoiding damage, unforeseen events and production slowdowns, and promoting better performance of daily work.

To be more specific, it should be noted that in some cases it is not possible to exceed a certain pressure level when using a machine. Thanks to the appropriate sensor, you can know in real time if the limit has been exceeded. Therefore, you have the opportunity to intervene manually and promptly, precisely to prevent any damage from affecting the entire instrument.

Finally, it is important to consider that a pressure sensor also makes it possible to understand when the machinery in question is not being used properly. Perhaps it needs a different pressure than the one being measured. Thanks to the sensor, it is possible to intervene and fully optimise the functions of the equipment in your possession.

Pressure sensor: our conclusions

As we can see, the sensor in question can take on great significance within a company, proving to be indispensable, to say the least. It allows you to monitor the functionality of your machinery and optimise its performance on a day-to-day basis. It also helps to avoid potentially negative situations and allows you to operate in a safer environment. All this is very important for modern companies, always looking for functional and innovative solutions, quality and efficiency in every aspect.

AEP transducers has an established presence on the market for the design, production and sale of strain gauge sensors and pressure transducers, electronic instrumentation and application software. Within our catalogue you will find many quality products, suitable to promote a better functioning of your machinery. Our laboratory is always working to guarantee precise, functional, durable and state-of-the-art products. We are therefore at your disposal to offer you more information on the pressure sensor and much more. We look forward to offering you customised solutions that are perfect for your working environment.

08

Jan 21Load cells: fields of application and recommendations for use

- 8 January 2021

- Redazione_AEP

- AEP transducers, load cells, measuring weight

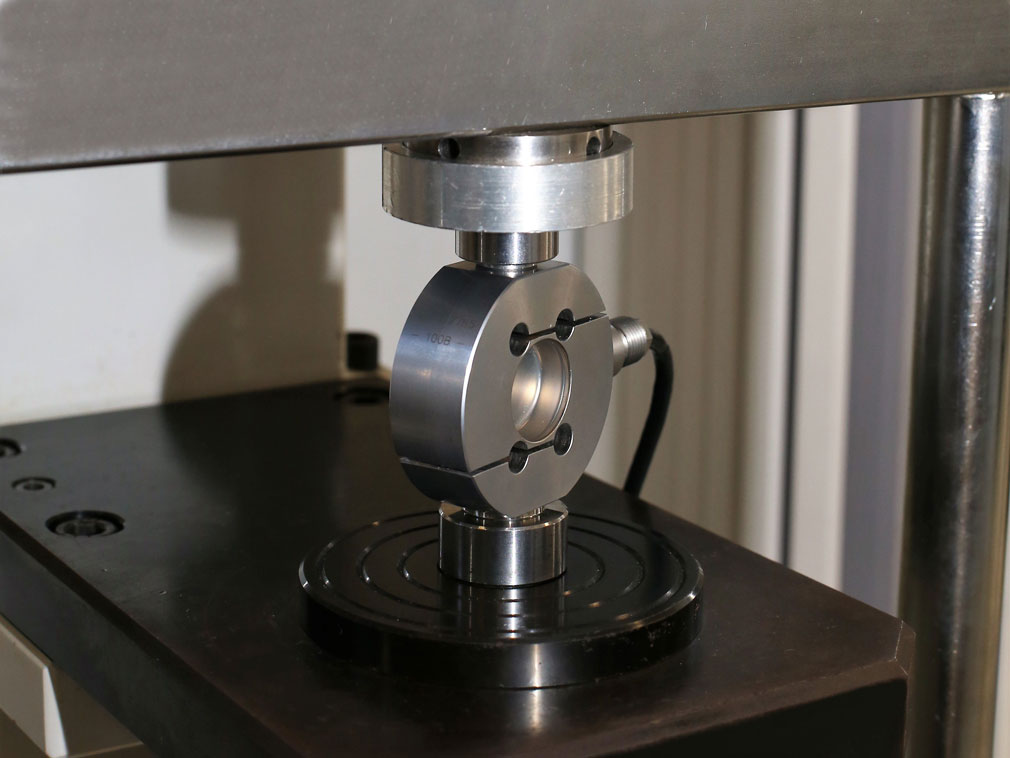

Load cells are used in many types of industries and in many situations. In many of these cases, it is important to know how they work and some tips for better use. Today we are talking about them in this short guide: What are the fields of application and tips for the best use of a load cell?

When using the load cell

This device is mainly used to measure the weight of various goods and objects. Therefore, it is useful within many industrial and commercial areas. It is interesting, however, to know that load cells can even be used inside beverage or food vending machines. In these situations, the device is used to sort the packs and make sure that they are all at the same height despite the different weights. In general, the most common fields of application for the cells are as follows:

- Weight measurement of railway wagons, ships or trucks.

- Measurement of the weight of food products for industrial packaging.

- Weight control for checking the quality of goods.

Load cells in the weighing field have different capacities and can measure from micrograms to tons.

The main advice for better use

Most of these devices have specific features and functionalities more or less peculiar. For this reason, before choosing a product of this type and using it, it is necessary to know its properties, operating modes and differences from other similar products.

These characteristics are especially important in terms of how the load cells are used and maintained. For example, some systems need to be cleaned every day and some also withstand particular stress or are able to operate under certain environmental conditions, while others do not. Therefore, it is essential to know in detail the device you are going to use.

Other suggestions not to be underestimated

In order to be sure that the cell can give optimal results, it is good practice to understand its range. It is also advisable to use the appropriate cleaning tools and products and use it only in an environment where it can operate well.

It should also be remembered that the material of which the load cells are made makes all the difference. In fact, for some people it is not recommended to use it in humid environments. For aluminium, on the other hand, it is suggested to avoid difficult weighing. Finally, it should not be forgotten that the preventive maintenance of weighing systems is always the best solution for those who want to save costs and count on the maximum efficiency of the devices.

Where can you find optimal load cells?

The advice we have just shared in this article will help you select the best product for you and make the best use of it. Don’t forget, however, that the support of experts can be very important, especially during the selection process. It will be essential to prefer quality, durable, resistant, precise and functional products.

We at AEP transduscers offer you our many years of experience in the design and production of ATEX-certified measuring instruments and sensors. We can guarantee you individual advice and solutions, as well as the most suitable load cells for your business. Please do not hesitate to contact us for more information.

01

Dec 20Nowadays, the company AEP transducers is known as one of the best in the field of production and sale of transducers, pressure gauges, dynamometers, electronic instrumentation for companies and much more. We are not saying this to boast, but just to tell you something about us.

Our company is located in Modena and operates in a very large factory, which exceeds 3000 square meters. Our staff focuses its attention on the continuous research of innovation and is constantly renewing our range of products, always offering the best to each customer.

Why choose AEP transducers? The reasons are not lacking

We have come a long way to offer our customers solid guarantees and, to date, there are many reasons to choose us. Below we list five of them. If you test us, however, you will discover that we offer many other advantages that should not be underestimated.

- Competence and professionalism at the service of the customer

Our great experience gained over the years has made AEP transducers a valid resource in the field of design and manufacture of measuring and calibration instruments. Our company has gained many years of experience in the production of certified sensors. Currently, we offer more than 200 consulting services per year on different types of applications. We can guarantee a competent and professional technical assistance, give you exhaustive answers and propose customized solutions.

Quality of materials and innovation

Quality of materials and innovation

Our customers come from all over the world. They rely on the precision and reliability of the devices we offer, but above all on the great quality we use in the production of our products.

The quality of the materials used in our factory is truly remarkable and allows customers to choose our technical solutions for their business. We are also able to provide a great technological innovation with regard to the instruments used for the sensors.

- Competitive and affordable prices for everyone

Despite the great quality of the products offered by AEP transducers, we still manage to keep prices affordable for everyone and very competitive for the sector we work in. This allows the end customer to count on a decidedly optimal quality-price ratio.

- Variety of products on offer

Another reason to choose us is this: the variety of products. Our expertise enables us to offer many different types of services, all of them of the highest quality, as well as a wide range of measuring products, equipped with advanced technology.

- Our production made in Italy

Finally, it is useful to underline that AEP transducers’ products are designed and manufactured entirely in the Modena plant. Our production is made in Italy, which leaves nothing to chance.

AEP transducers is waiting for you

Every year we invest a large part of our turnover in the production of increasingly technological products. Therefore, we have what it takes to optimise and simplify the various business activities. We at AEP transducers are looking forward to offering you customised, state-of-the-art solutions, from strain gauge sensors to electronic instrumentation and application software.

Quality of materials and innovation

Quality of materials and innovation