25

Jan 21Thanks to various studies and advances in the field of technology, for some time now we have had different types of transducers available. Today we are talking about force, displacement and pressure transducers. What are their characteristics?

A brief introduction to these interesting devices

Before going into detail, it is useful to say that a transducer is a particular device capable of converting a given physical quantity into another. In practice, it receives an input signal and proposes another at the output. Some transducers are also capable of transforming one type of energy into another.

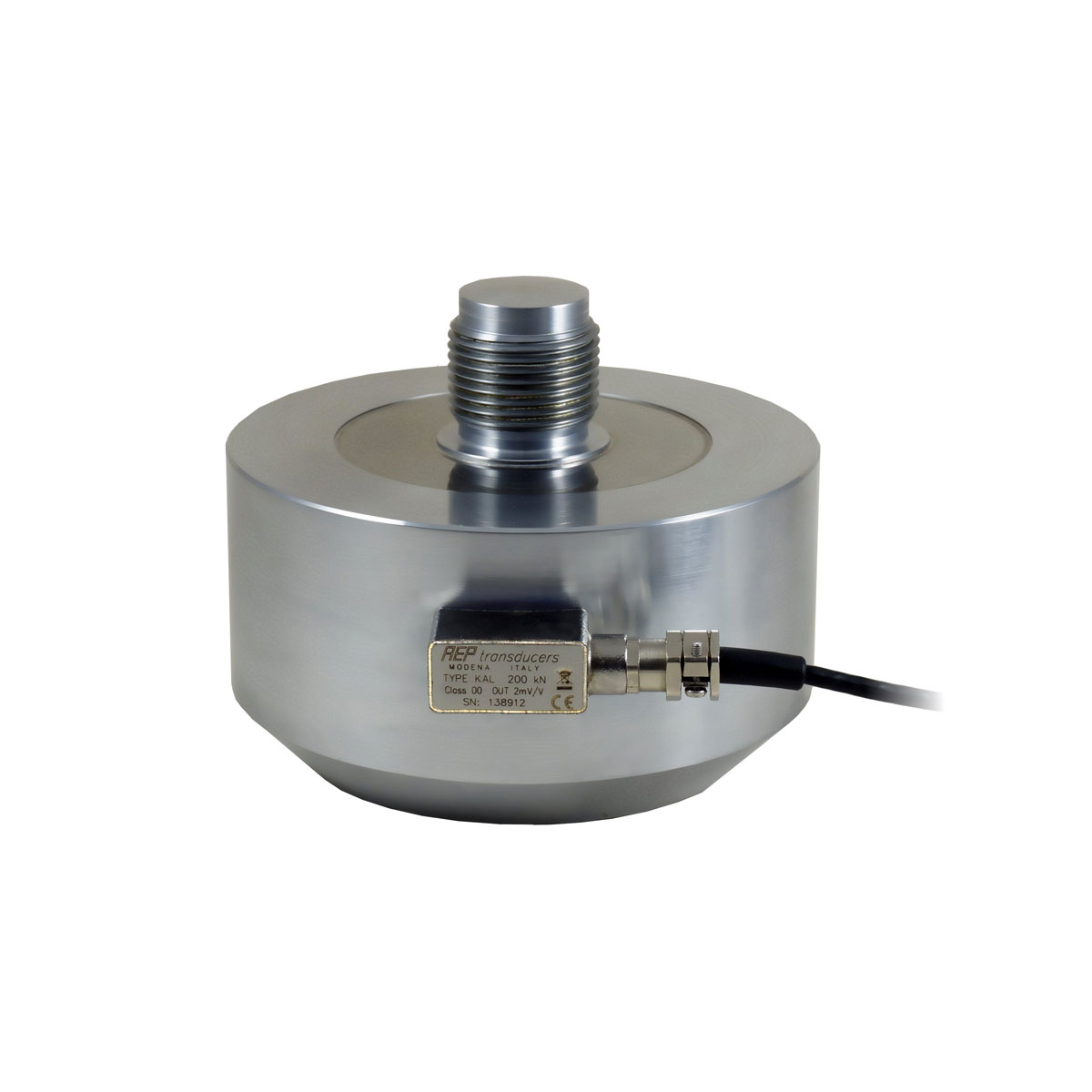

Characteristics of force transducers

Force transducers are sensors that transmit the force itself in a different magnitude or change only some of its characteristics. They are used in various sectors, both in industry and in more common applications. There are basically two types of force transducers: homogeneous force transducers and non-homogeneous force transducers, also called “hybrids”.

Pressure and displacement transducers fall into the category of force sensors. This is because pressure is defined as a force per unit area.

Displacement transducers

Displacement transducers are also called “displacement sensors”. They prove to be instruments which ensure that the results of calculations in certain areas of research and development are correct. All transducers of this type operate on the principle of inductive measurement.

They are easy to use, compact and robust, and offer high levels of accuracy. They also tend to wear out slowly. A displacement sensor can be used for a variety of purposes: from high-precision measurements in the micrometre range to simple monitoring in production.

Pressure transducers

A pressure transducer converts the pressure it receives as input into an analogue electrical signal. This conversion is triggered by the deformation of the strain gauges inside the device. In practice, the applied pressure deforms the strain gauge, which then changes its electrical resistance in proportion to the pressure. Again, these are instruments that, if chosen carefully, operate independently, functionally and accurately, and can last a long time.

What is the ideal transducer? AEP transducers solutions

Choosing the right transducer for your business may not be as simple as it may seem at first glance. That’s why we at AEP transducers stand by our customers and offer comprehensive and personalised support. Thanks to our many years of experience, we guarantee the design and manufacture of quality, tested and certified transducers.

We offer a wide range of force, displacement and pressure transducers. Our solutions are reliable, functional, efficient and durable. With this in mind, we invite you to put us to the test. Contact us as soon as possible for more information and advice tailored to your needs and preferences.

24

Nov 20The use of pressure transducers: characteristics and solutions to consider

- 24 November 2020

- Redazione_AEP

- pressure transducer maintenance, pressure transducers

Today we are talking about the use of pressure transducers, fundamental instruments in certain sectors, which have a very precise objective: to improve the use of water, gas and various fluids. Let’s go into detail and see what the main features of these important devices are.

What is a pressure transducer for?

This particular instrument is of fundamental importance in all those sectors where liquids and various types of fluids are used. The instrument in question is used to measure the force of the pressure exerted by these fluids while they are under stress.

Certain machines operate only and exclusively when this value reaches a certain level. For this very reason, it is important to use pressure transducers. They allow you to assess whether you need to apply more or less pressure and ensure that that level can be reached without risking damage to the machinery.

Pressure transducers: how do they work?

As far as the operation of pressure transducers is concerned, it is important to take into account the fact that this instrument is equipped with a particular sensor, which can be fine or coarse-pointed. Depending on the type of fluid used, it will be necessary to use a different tip, which can guarantee less or greater precision.

This sensor must be positioned at the exact point where the fluid is to be measured. Subsequently, you will notice that the sensor will record the pressure. The detected value will then be made known by means of an electromagnetic pulse.

Maintenance operations to consider

It is useful to know that pressure transducers need to be serviced regularly. This will allow you to always have a high-performance instrument at your disposal, capable of ensuring the recording of correct values. Therefore, when purchasing and implementing the transducer, it is advisable to find out how and at what intervals the necessary maintenance should be carried out.

Our transducers, ideal for your business

If you need to keep the pressure of a fluid under control during your production processes and want to prevent a machine from actually being damaged, you should certainly use this tool. You can select pressure transducers directly from our catalogue.

We have been involved in the design and production of this type of device and many others for years. Our pressure transducers range from 100 mbar to 2500 bar. We offer versions for relative, absolute, vacuum and differential measurements, amplified and non-amplified, with an accuracy class from 1.0% to 0.05%.

We are waiting for you to guarantee you diversified and quality solutions

Our products guarantee high reliability every time, thanks to our production processes and careful selection of raw materials. We use precise instruments able to guarantee the production of high performance products from every point of view.

Precisely for these reasons, we serve customers all over the world, who rely on our precision and our technical solutions for different types of business. Do not hesitate to ask us for more information about pressure transducers and more.